|

|

|

|

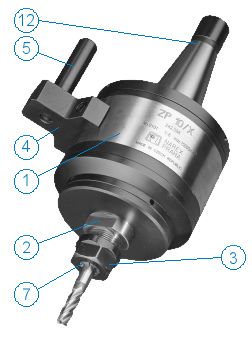

Product description ZP-10/X -

Spindlespeeder |

|

|

|

|

ZP-10/X - legend

1 - garland

2 - spindle

3 - collet nut

4 - arresting device

5 - arresting pin

7 - collet

12 - taper shank Basic technical data

-

gear ratio 1:6

-

spindle speed 20.000 RPM

-

power 4,5 kW

-

tool diameter 1,0÷13,0 mm

-

collet ER20/ESX

-

possibilities of clamping ISO 40 DIN 2080, ISO 50 DIN 2080,

ISO 40 DIN 69871, ISO 50 DIN 69871, CAT 40, CAT 50, BT 40, BT 50, ISO 40 ČSN 220432, MT4, MT5, MT6

|

|

|

ZP-10/X- Spindlespeeder is basically collet chuck of drills

and shank mills, equipped by mechanical planetary transmission with fixed ratio of overdrive 6:1. Spindle (2) is

modified for straight shanks clamping in range 1,0÷13 mm by collets (7) type ER20/ESX DIN 6499-B. Maximal

short-term available spindle revolutions are given by the bound 20.000 rpm, ordinary usage of instrument is up

to 15.000 rpm by allowed working temperature to 50°C.

Apparatus is clamped into the

spindle of drilling machine by taper shank (12) and by arresting

device (4,5) is garland (1) – gear of planetary transmission hold out of motion.

Apparatus can be used in vertical or horizontal position on milling, boring or drilling machines

designed for steel, cast-iron, coloured metals, light metal and plastic material machining. When it is used on CNC

machine, then can be used bin of appliance if possibilities of machine are suitable for it (max. stowing corporeality

and dimensions).

Application

-

as a special accessories for milling, boring, drilling, NC and CNC machines

-

for precise and productive milling and boring with high cutting speeds

Notice !

|

|

|

|

|

Dealers |

|

|

|

General Dealers Czech Republic

|

Facilitation

|

|

|

- M &

V, spol. s r.o. (Vsetín)

4. května 288, CZ-755 01 Vsetín

tel: 420-571 484 817

fax: 420-571 413 126

www.mav.cz

Údolní 40, CZ-602 00 Brno

tel: 420-543 216 868

fax: 420-543 249 300

www.tti.cz

Bratislavská 49, CZ-602 00 Brno

tel: 420-545 212 092

fax: 420-545 211 163

www.stimtools.cz

Mezi ploty 12, CZ-326 00 Plzeň

tel: 420-377 242 058

fax: 420-377 243 161

www.hofmeister.cz

Přítkovská 152, CZ-417 12 Teplice-Proboštov

tel: 420-417 560 721

fax: 420-417 560 385

www.bos-teplice.cz

Osvobození 129, CZ-763 16 Fryšták

tel: 420-577 110 711

fax: 420-577 110 733

www.hanak.cz

|

Slovakia

Farská 86/2

SK-019 01 Ilava

phone: 421-424 466 316

fax: 421-424 464 279

www.ntv.sk

- M&V, Slovakia spol. s r.o.

Vsetínská cesta 1487-9

SK-020 01 Púchov

phone: 421-424 634 548

fax: 421-424 634 549

www.mavslovakia.sk

Sumracná 27

SK- 821 02 Bratislava

phone: 421-243 338 080

fax: 421-243 335 501

www.osan-bratislava.sk

Horská 1311/2

SK-958 06 Partizanské

phone: 421-387 491 373

fax: 421-387 491 373

www.panas.sk

|

|

|

|

|

|

|

|

|

Manuals for Spindlespeeders - download in PDF |

|

|

|

ZP-10/X -Spindlespeeder

|

Facilitation

|

|

|

|

|

|

|

|

|

Frequently asked questions (FAQ)

|

|

|

|

Firm NAREX MTE produces and deliveres following:

ZP 10/X - basic construction - (catalogue),

ZP 10/XW - construction with inner coolant - (figure),

ZP 20/X - basic construction,

ZP 20/XW - construction with inner coolant |

|

|

Construction ZP 10/X is delivered within 2 - 4 weeks other constructions during 8-12 weeks after

receiving order. |

|

|

It is

construction for manual or automatic exchange with cooling fluid bypass (type

A) |

|

|

ZP 10/X-overdrive 6:1, max. 20.000RPM,

ZP 10/XW-overdrive 6:1, max. 11.000RPM, with max. press of cooling fluid 20

bar,

ZP 20/X-overdrive 5:1, max. 15.000RPM,

ZP 20/XW-overdrive 5:1, max. 7.000RPM, with max.

press of cooling fluid 20 bar |

|

|

It is because of the maintenance sealing component acceptable durability. |

|

|

Drills and shank mills from HSS or from

hardmetal with straight shank. They are clamped to the steel collet. Range:

by ZP 10/X and ZP 10/XW 1,0 - 13,0 mm collet ER 20,

by ZP 20/X and ZP 20/XW 2,0 - 20,0 mm collet ER 32

|

|

|

A - clamping spindle cavity must be in such condition that the clamping is accurate and rigid.,

B - spindle and machine table seating must has necessary rigidity to prevention undesirable vibration during machining. |

|

|

It is necessary to measure spindle run-out on the cavity edge

for collet. Value of run-out can not be higher than 0,02 mm. If this is fulfilled than can be by collet

slewing and clamping tool again found optimal run-out value. |

|

|

In instruction for use are given basic conditions that are

necessary to adhere. This machine is not designed for stocking or big load but for speed machining

by small diameters of cutting tools. Maximum revolutions you find in the item 4 of this document,

maximum feed on mill teeth can not be higher than 0,025mm and maximum sliver depth is 0,5 d

(tools diameter). |

|

|

A - choose mill with more teeth, B - minimize run-out of clamping tool,

C - adjust cutting conditions |

|

|

A - take out machine vibration, B - exchange blunt toll for new,

C - adjust cutting conditions, D - change cutting liquid |

|

|

Devolve it on producers to diagnose its sort and relevant repair. |

|

|

|

|

Product repairing

|

|

|

|

NAREX MTE standardly provides repairs of produced and delivered products.

There are guarantee repairs or normal non guarantee repairs. During repair

is product dismounted, there are found defective parts and up to it is determined

range and price of repair. After customer´s repair price confirmation are defected

parts exchanged, product is again mounted and tested.

Repair speeding

For repair speeding and lower price is suitable to enclose to repair order letter with

information about problems (during which conditions defects occurs or indicate required range of repair).

Repair ordering

For repair ordering you should send product for repair, order of repair and specifications of defects on our address:

NAREX MTE s.r.o.

sales department

Kreslicka 1, building D

CZ-101 00 Prague 10

Czech Republic

Information about repair

About repair you will be informed by e-mail or by phone, with any

questions you can contact export department on phone: +420

725 551 171, e-mail:

sales@narexmte.cz. |

|

|

|

|

|

NAREX MTE s.r.o.

Kreslicka 1, building

D

CZ-101 00 Prague 10

Czech Republic |

|

Tel:

|

+420-725 551 171

+420-602 675 763

|

|

e-mail:

sales@narexmte.cz

http://www.narexmte.cz |

|

|

|

|

|

Support

|

|

|

|

Technical support is at the disposal of you on phone

+420 725 551 171 or you can contact us by e-mail:

sales@narexmte.cz.

Basic technical information you can find also on reference

service. |

|

|

|

|

|

|

|

|

NAREX MTE s.r.o.

Kreslicka 1, building

D

CZ-101 00 Prague 10

Czech Republic |

|

Tel:

|

+420-725 551 171

+420-602 675 763

|

|

e-mail:

sales@narexmte.cz

http://www.narexmte.cz |

|

|

|

|

|

|

|

|

|

| |

|

- Catalogue of Milling tools (PDF)

|

|

|

česky

english

deutsch

|

|

|

|

|

| |

|

- Milling angle heads Fuh (PDF)

|

|

|

česky

english

deutsch

|

|

|

|

|

| |

|

- Spindlespeeder ZP-10/X (PDF)

|

|

|

česky

english

deutsch |

|

|

- Display of products lines (quick reference)

|

|

|

|

|